High-Speed Spin Coating Production Line for Pulp Mold Waterproofing | Tailored Configuration

รายละเอียดสินค้า:

| สถานที่กำเนิด: | จีน |

| ชื่อแบรนด์: | Osmanuv |

| ได้รับการรับรอง: | CE |

| หมายเลขรุ่น: | OSM-XT-1024T |

| เอกสาร: | PULP MOLDING AUTOMATIC SPIN...NE.pdf |

การชำระเงิน:

| จำนวนสั่งซื้อขั้นต่ำ: | 1 ชุด |

|---|---|

| ราคา: | negotiable |

| รายละเอียดการบรรจุ: | กล่องไม้ |

| เวลาการส่งมอบ: | 45 วัน |

| เงื่อนไขการชำระเงิน: | t/t |

| สามารถในการผลิต: | การเจรจาต่อรอง |

|

ข้อมูลรายละเอียด |

|||

| แรงดันไฟฟ้า: | 220V 50Hz | คุณสมบัติด้านความปลอดภัย: | การป้องกันความร้อนสูงเกินไป |

|---|---|---|---|

| พลังงานทั้งหมด: | 170kW | ประเภทจาน: | แผ่นรูดด้า |

| วัสดุเคลือบ: | การเคลือบ UV | แบรนด์อินเวอร์เตอร์: | ชไนเดอร์ |

| คุณสมบัติ: | ประสิทธิภาพสูง ใช้งานง่าย บำรุงรักษาต่ำ | ||

| เน้น: | high-speed pulp molding coating machine,spin coating production line waterproofing,custom pulp molding coating equipment |

||

รายละเอียดสินค้า

High-Speed Spin Coating Production Line for Pulp Mold Waterproofing | Tailored Configuration

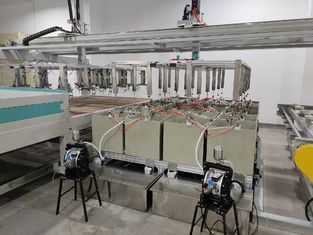

Composition of Production Line

This advanced spin coating system features an automated feeding conveyor, precision rotary coating stations with servo-driven rotation, infrared pre-heating zone, high-speed spinning units, UV curing tunnel, quality inspection system, and automated stacking output. The line can be fully customized with additional coating layers or special drying requirements.

Product Description

Our high-speed spin coating production line specializes in applying perfect internal waterproof coatings for pulp molded products. Utilizing centrifugal force technology, it ensures uniform distribution of barrier coatings with precise thickness control, making it ideal for food packaging and liquid containers requiring exceptional leakage protection.

Technical Parameters

| Parameter | Specification | Notes | |

|---|---|---|---|

| Model | HSC-800W | HSC-1200W | Custom sizes available |

| Production Speed | 40-60 pcs/min | 60-80 pcs/min | Adjustable based on product size |

| Coating Thickness | 10-100 μm | Precision control ±2 μm | |

| Rotation Speed | 500-5000 RPM | Digital servo control | |

| Curing Method | UV or Thermal | Customizable based on coating material | |

| Power Requirements | 380V/50Hz/3Phase | Voltage customization available | |

| Coating Waste | <3% | Closed-loop recycling system | |

| Control System | Industrial PC + Touch屏 | Recipe storage for 100+ products | |

| Air Pressure | 0.6-0.8 MPa | Built-in pressure stabilization |

Application

Perfect for waterproof internal coating of:

-

Disposable food containers (soup bowls, takeaway boxes)

-

Beverage cups and liquid packaging

-

Medical and laboratory disposable products

-

Flower pots and agricultural containers

-

Electronic equipment packaging

Customization

We provide completely tailored solutions including:

-

Customized coating thickness for specific waterproof requirements

-

Additional coating layers for enhanced barrier properties

-

Specialized curing systems for different coating materials

-

Integration with existing production facilities

-

Automated quality inspection and sorting systems

-

Multi-language interface and control systems

Feature

-

Waterproof Excellence: Achieves IP67 rating for liquid protection

-

High-Speed Operation: Maximizes production efficiency

-

Energy Saving: 30% less energy consumption than conventional methods

-

Quick Changeover: <5 minutes for product size changes

-

Intelligent Monitoring: Real-time coating thickness detection

-

Minimal Maintenance: Self-cleaning system reduces downtime

Support and Services

-

Free sample testing and process development

-

On-site installation and operator training

-

24-month warranty on main components

-

Remote troubleshooting and maintenance support

-

Regular software updates and technical improvements

-

Spare parts supply guarantee

Packing and Shipping

-

Heavy-duty export packaging with waterproof protection

-

Customized crating for sensitive components

-

Complete shipping documentation handled professionally

-

Worldwide delivery with tracking information

-

On-time delivery guarantee

FAQ

Q: What is the minimum waterproof standard you can achieve?

A: Our standard systems achieve IP67 protection, with higher levels available through customization.

Q: How do you handle different product shapes?

A: Our programmable rotation algorithms automatically adapt to various product geometries.

Q: Can the system handle plant-based waterproof coatings?

A: Yes, we have extensive experience with both synthetic and bio-based coating materials.

Q: What is your typical lead time for custom systems?

A: Usually 10-12 weeks after final design confirmation.

Q: Do you provide technical support for coating material selection?

A: Yes, we offer comprehensive material testing and recommendation services.

Q: How often does the system require maintenance?

A: Recommended quarterly preventive maintenance, with remote monitoring available.

Q: Can the line be upgraded after installation?

A: Yes, our modular design allows for future upgrades and capacity expansion.